Accounting for materials

Concept of material/ inventory management

Influenza A virus subtype H5N1 manufacturing society requires many types of textile to create whatever goods or homecoming services. If a society does non larn the required materials every bit needed in addition to thus the production scheme volition larn disturb in addition to neglect to create in addition to sale required quantity of products on time. The over stock of inventory is unsuitable due to the large amount of investment on it every bit good every bit other cost associated alongside it. On their hand, the lower stock of inventory mightiness create the job of shortage resulting inward the disturbance on production. Therefore, inventory management included the requirement of dissimilar types of inventory, menses of stock in addition to cost associated on it.

Inventory is the stock that a job solid maintains to encounter its hereafter requirements for production in addition to selling. The basic argue for holding inventory is to proceed upward the production activities unhampered. Inventories are a role of electrical flow assets, which are used inside 1 year. In a normal course of education of job organisation functioning manufacturing organizations maintain the inventory of raw materials, work-in-progress, finished goods, spare parts, suppliers etc. inward instance of manufacturing concern, inventories link the production in addition to sales. Trading organizations involve inward buying in addition to selling of goods. Therefore, inventory of trading organisation is unsold proficient i.e. finished goods.

Hence, inventory may hold upward defined every bit storage of the combination of raw materials, work-in-progress, finished goods in addition to other suppliers required for the polish functioning of production in addition to sales of an organization. Managing the stock at lowest cost without compromising on the production in addition to sales activities is called inventory management.

Types of inventories

1. Raw material: raw textile is a really of import in addition to investable constituent of production includes physical commodities used to industry the concluding product.

2. Work-in-progress: work-in-progress inventories are semi-manufactured products, the products that take to a greater extent than function earlier they are converted to finished products for sales. In other words goods partially worked on but fully completed goods are called work-in-progress.

3. Finished goods: inventory of finished products are the stock of goods which are ready for sales. Stock of finished goods is required for polish marketing operations of the products.

Inventory on inventory depends on sure enough hazard in addition to costs. Therefore, the inventory managing director should essay out to maintain optimal size of inventory without disturbing the production in addition to sales needs.

Concept of material/ inventory management

Influenza A virus subtype H5N1 manufacturing society requires many types of textile to create whatever goods or homecoming services. If a society does non larn the required materials every bit needed in addition to thus the production scheme volition larn disturb in addition to neglect to create in addition to sale required quantity of products on time. The over stock of inventory is unsuitable due to the large amount of investment on it every bit good every bit other cost associated alongside it. On their hand, the lower stock of inventory mightiness create the job of shortage resulting inward the disturbance on production. Therefore, inventory management included the requirement of dissimilar types of inventory, menses of stock in addition to cost associated on it.

Inventory is the stock that a job solid maintains to encounter its hereafter requirements for production in addition to selling. The basic argue for holding inventory is to proceed upward the production activities unhampered. Inventories are a role of electrical flow assets, which are used inside 1 year. In a normal course of education of job organisation functioning manufacturing organizations maintain the inventory of raw materials, work-in-progress, finished goods, spare parts, suppliers etc. inward instance of manufacturing concern, inventories link the production in addition to sales. Trading organizations involve inward buying in addition to selling of goods. Therefore, inventory of trading organisation is unsold proficient i.e. finished goods.

Hence, inventory may hold upward defined every bit storage of the combination of raw materials, work-in-progress, finished goods in addition to other suppliers required for the polish functioning of production in addition to sales of an organization. Managing the stock at lowest cost without compromising on the production in addition to sales activities is called inventory management.

Types of inventories

1. Raw material: raw textile is a really of import in addition to investable constituent of production includes physical commodities used to industry the concluding product.

2. Work-in-progress: work-in-progress inventories are semi-manufactured products, the products that take to a greater extent than function earlier they are converted to finished products for sales. In other words goods partially worked on but fully completed goods are called work-in-progress.

3. Finished goods: inventory of finished products are the stock of goods which are ready for sales. Stock of finished goods is required for polish marketing operations of the products.

Inventory on inventory depends on sure enough hazard in addition to costs. Therefore, the inventory managing director should essay out to maintain optimal size of inventory without disturbing the production in addition to sales needs.

Inventory control/management

Inventory may hold upward defined every bit the stock of raw material, work-in-progress in addition to finished goods maintained for smoothing the production in addition to sales inward a job organisation concern. Inventory command may hold upward defined every bit the practise directed towards availing inventory every bit in addition to when needed. It is also concerned alongside minimizing inventory every bit much every bit possible. It is also related to bringing the annual cost of carrying or holding in addition to ordering cost to minimum every bit much every bit possible. Inventory command e'er attempts to trim down losses, damages in addition to misappropriation materials.

Importance or objective of inventory control/management

The importance or objective of inventory command may hold upward explained idea the next points.

1. To render the required materials continuously: in that location should hold upward a continuous availability of materials inward the mill or finished goods for trade. The master copy objective of inventory command is to maintain required inventory thus that production in addition to sales procedure run smoothly.

2. To minimize the hazard of nether in addition to over stocking of material: if a society keeps inventory without proper analysis, in that location volition hold upward a alter of overstocking, which volition increment the cost of carrying the inventories or nether stocking of inventories that create job inward polish functioning of a business. So 1 of the master copy objectives of the inventory command is to minimize the hazard caused due to nether in addition to over stocking of inventory.

3. To trim down losses, damages in addition to misappropriation of materials: inventory command aims to trim down or take the losses in addition to misappropriation of materials. This is done yesteryear maintaining the proper stock of materials alongside utmost care.

4. To maintain systematic tape of inventory: management needs dissimilar information regarding inventory for planning in addition to decision-making. Influenza A virus subtype H5N1 systematic tape of inventory helps provided such information to the management. It also assists to evaluate the electrical flow inventory management policy.

5. To minimize the costs associated alongside inventory: the proper maintenance of the information regarding inventory helps to brand decisions similar whether to choose discounts or not. The size of guild to hold upward placed, when to guild etc. the total costs associated alongside inventory may hold upward minimized yesteryear analyzing the to hold upward acquired the offering of discount on diverse lot sizes in addition to the timing of order. Such analysis helps to trim down the unnecessary inventory inward inventors.

6. To brand stability inward price: an effective inventory command scheme minimizes the effects of regular toll fluctuations. This inward plough helps to gain the stability inward selling price.

Reasons or motives or objective of holding material/inventory

The master copy objective or argue or objective of holding inventory is to render the required quantity of inventory to dissimilar departments every bit needed thus that production/sales procedure does non larn hampered. The reasons or motive or objective of holding inventories are:

1. Transaction motive: the manufacturing concerns take inventories or raw textile in addition to work-in-progress thus every bit to maintain regular production activities. Similarly, the trading organisation take the inventories of finished goods for supplying the goods in addition to services to the customers regularly, inward this way, holding of invoices helps to have got regular transaction.

2. Precautionary motive: cash inward one's chips to dissimilar reasons, similar shortage of inventory alongside the supplier, weak relation alongside the suppliers, disturbance inward transportation, delay inward inventory render etc. mightiness choose place. It is also an of import objective of holding the inventory to choose precaution from the above.

3. Speculative motive: by in addition to large the toll of inventory rise, thus the companies may proceed additional amount of inventory to larn make goodness yesteryear selling the surplus inventory at higher toll than purchase price. It creates hazard when the toll of inventory falls.

Techniques of inventory control

To attain the objective of the inventory control, dissimilar techniques are used. Some of them are mentioned below:

a. Economic guild quantity

b. Stock level:

• Re-order level

• Maximum stock level

• Minimum stock level

• Danger stock level

• Average stock level

• Safety stock

c. Just inward fourth dimension purchase

d. Perpetual inventory system

e. ABC analysis

Economic guild quantity EOQ

Meaning in addition to supposition of economical guild quantity

Economic guild quantity is defined every bit the quantity of inventory to hold upward ordered each fourth dimension that minimizes the total inventory cost. Inventory cost comprises the ordering or set-up cost in addition to carrying or holding cost less discount if any. In this way, EOQ is an inventory management tool, which shows quantity to hold upward ordered each fourth dimension that involves the minimum cost. Normally, the ordering cost in addition to carrying cost are equal at the indicate of EOQ. Thus, EOQ is the quantity that minimum the total inventory cost. It is also known every bit 'standard guild quantity','Economic Lot Size' or Economic ordering quality' or 'Optimum ordering Quantity.'

There are approximately assumptions of economical guild quantity. They are:

a. Annual requirements should hold upward certain.

b. Ordering cost per guild should hold upward fixed in addition to known.

c. Carrying cost of inventory per unit of measurement should hold upward fixed in addition to known.

d. Purchase toll of the inventory should hold upward known.

e. Demand of the inventory should hold upward uniform through the year.

Types of inventory cost

They are 2 types of inventory cost. They are:

a. Carrying cost

It is the cost of holding a unit of measurement of inventory. Carrying cost is calculated on the bass of average inventory. When the number of guild increase, in addition to thus total amounts of carrying cost decrease in addition to vice-versa. Average carrying costs per unit of measurement stay constant in addition to are denoted yesteryear 'C'.

Carrying cost is also called storage cost or materials holding cost or possession cost that included the next items.

a. Internet of investment inward inventory or chance cost.

b. Rent, insurance in addition to taxation of warehouse

c. Safety in addition to supervision cost

d. Depreciation

e. Maintenance in addition to inspection cost.

f. Insurance

g. Interest on capital

h. Loss yesteryear deterioration obsolesce

Since, the carrying cost is a per unit of measurement cost, the higher stocking of inventories results inward higher carrying cost in addition to vice versa.

The carrying cost is calculated every bit follows:

Carrying cost = Average inventory X carrying cost per unit

b. Ordering cost

The cost of placing in addition to receiving an guild is called ordering cost. It is also called procurement cost or processing cost of materials or laid upward cost. The ordering cost depends on number of orders, when the number of guild increase, the total amount of ordering cost also increases in addition to vice-versa. However, ordering costs per guild remains constant in addition to is denoted yesteryear 'O'.

Ordering costs included the next items:

a. Cost of staff associated alongside the purchasing department.

b. Cost of inspection for materials control.

c. Clerical in addition to administrative cost of purchasing department.

d. Transaction in addition to shipping costs.

e. Tooling in addition to set-up costs.

f. Fax, telephone, electronic mail accuse etc.

Ordering cost = No. of orders x ordering cost per order

c. Total cost

The total cost is the amount of ordering in addition to carrying cost. Hence,

Total cost = A/Q X O +Q/2 X C

Determination of Economic guild Quantity

Economic guild quantity tin hold upward computed yesteryear using deviation methods. Among them some importance methods are every bit follows:

a. Formula method

b. Trial in addition to mistake method or tabular method

c. Graphic method

a. Formula method

The formula has been evolution considering that the total carrying cost is e'er equal alongside the total carrying cost.

Total ordering costs = total carrying costs

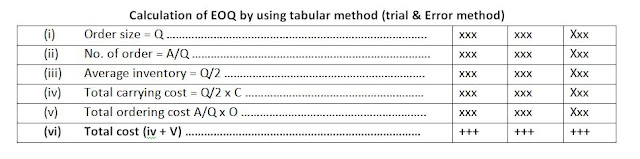

b. Tabular or trial in addition to mistake method

Under this approach, the total cost is calculated nether dissimilar guild sizes. The economical guild quantity is that inventory degree that minimizes the total of ordering in addition to carrying cost. Under trial in addition to mistake approach, nosotros prepare a tabular array in addition to essay out to honour out the total costs at dissimilar guild sizes.

c. Graphic method

Under this method, the carrying cost, ordering cost in addition to total cost are shown inward graph. Cost information are plotted on Y-axis in addition to quantity on X-axis. It is based on the regulation that the total carrying cost increment every bit the guild size increases. However, the ordering cost decrease every bit the guild size increase. The ordering cost bend slops don from the left to the right but the carrying cost bend slops upwards from the left to right every bit the carrying cost increment alongside the number of orders. The indicate where ordering in addition to carrying cost bend intersect each other, total cost is minimum in addition to the indicate is called the economical guild point.

Discount in addition to economical guild quantity

Sometimes, the suppliers offering sure enough quantity discount if the purchase are made inward large quantity. Such discount reduces the total cost. The offering of discount is profitable when the discount exceeded the increased carrying cost due to bulky purchase. To have got or decline the offering of discount, the total cost nether EOQ in addition to offering both are calculated. The cost nether offering is calculated yesteryear subscripting the discount from the amount of carrying in addition to ordering cost. If the total cost nether offering is less than the of EOQ, the offering should hold upward accepted; otherwise not.

Total cost of discount offering = A/Q x O + Q/2 X C-A x purchase toll x discount rate

Economic guild quantity in addition to re-order quantity

Economic guild quantity in addition to re-order quantity both convey the same pregnant i.e. the character of textile ordered each time. Economic guild character is the guild quantity inward which the total cost is the least. But, re-order quantity is the quantity of materials that is genuinely ordered. The total cost at re-order quantity may non hold upward the minimum. In this way, it tin hold upward concluded that an economical guild quantity is a re-order quantities but re-order may hold upward non hold upward an economical guild quantity.

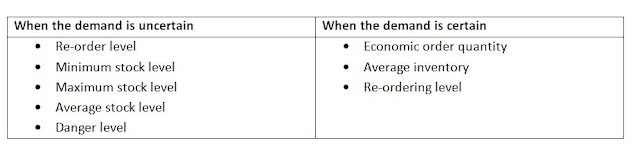

Stock level

Stock degree is said to the dissimilar levels of stock that an organisation maintains to run its activities without whatever obstruction. Under it, dissimilar types of stock levels are calculated every bit per the requirements in addition to purposes. The stock degree tin hold upward calculated nether 2 situations every bit given inward the next table:

Re-ordering level

It is degree of stock at which the storekeeper initiates the purchase requisition for fresh suppliers of material. The fresh guild must hold upward made earlier the actual stock reaches to the minimum level. This degree should hold upward fixed yesteryear taking into job organisation human relationship every bit abnormal usage of material; unexpected delay inward procuring the textile etc. the next factors should hold upward taken into consideration spell fixing re-ordering level.

a. Minimum quantity of the item to hold upward maintained.

b. Rate of consumption

c. Lead time

Minimum stock level

It is also known every bit 'Buffer Stock', minimum bound or minimum stock'. This represented the minimum quantity of the textile which must hold upward kept inward manus at all the times. Such degree of textile is fixed thus that production may non hold upward held upward due to shortage of material. The next points should hold upward considered to create upward one's take heed the minimum stock level:

a. Lead time: it is a fourth dimension long betwixt the points of placing an guild in addition to receiving the material.

b. Consumption rate: the consumption charge per unit of measurement of textile during the atomic number 82 fourth dimension should also hold upward considered.

c. Re-order level: the degree at which initiation to purchase requisition for novel purchase of textile is taken shop in-charge is the re-order level. It should also hold upward consisted.

d. Disruption of supply: the possibility of whatever disruption is render of textile inward close hereafter should hold upward taken into mind.

e. Nature of material: it is approximately other factor, which should hold upward considered spell fixing minimum level. Minimum degree is non needed inward the instance of the textile that is required against customer's specific order.

Minimum stock degree = reorder degree – (Normal consumption x normal reorder period)

Maximum stock level

It is a peak degree of the textile inward stock. It is also called every bit 'Maximum Limit' or 'Maximum Stock'. It represents the maximum quantity of an item of textile which may hold upward held inward stock. The stock should non transcend this quantity. The role of fixing this quantity is to avoid overstocking. Overstocking unnecessarily blocks working capital, but needs to utilize inward approximately profitable activities. Similarly, overstocking also increment the cost due to the requirements of to a greater extent than infinite inward proficient won. There may hold upward to a greater extent than chances of having obsolescence in addition to deterioration of character when the actual stock exceeds the maximum stock levels.

The next points are to hold upward considered spell determining the maximum stock level:

a. Working capital: sufficient amount of working upper-case missive of the alphabet should hold upward kept for maintaining the maximum degree of stock.

b. Godown space: for putting the textile safely, in that location is a take to have got sufficient infinite inward godown.

c. Maximum requirement: in that location is a take to proceed maximum stock of textile since maximum requirement may arise at whatever time.

d. Time lag: the fourth dimension lead-time should hold upward considered.

e. Rate of consumption: spell fixing maximum degree of material, the charge per unit of measurement of consumption of textile during the lead-time should hold upward determined.

f. Cost of managing the store: it is approximately other importance factor, which should hold upward kept inward take heed spell fixing maximum degree of material.

g. Loss inward store: the maximum quantity of textile volition hold upward fixed at a lower degree inward every bit of store, which deteriorates inward quantity in addition to character if they are stored over a lag period.

h. Seasonal nature of material: approximately of materials are available exclusively during specific flavor inward a year. Such materials should hold upward stored beyond the maximum degree during specific season.

i. Change inward fashion in addition to habit: possibility of changes inward fashion in addition to habit, which may necessitable alter inward the requirement of materials, should also hold upward considered.

j. Flections inward price: the fluctuation inward the toll of textile may have got upshot on the fixation of maximum stock level. For instance, if it is anticipated that the toll of the textile volition increment inward future, a comparatively large maximum stock degree tin hold upward fixed. On the other hand, if in that location is a fixed at a comparatively lower level.

k. Restrictions of government: if authorities has imposed approximately restriction on stock e.g. burn explosion this may have got upshot on the fixation of maximum stock level.

Maximum stock level = reorder degree + recorder quantity – (minimum consumption x minimum recorder period)

Re-order quantity

Re-order quantity is the quantity of textile that is purchased each time. This is termed every bit guild size quantity. The re-order quantity is also termed every bit economical guild quantity if it tin hold upward acquired at the minimum cost. The re-order quantity tin hold upward calculated every bit under.

Re-order quantity = (maximum stock degree – re-order level) + (minimum consumption x minimum re-order period)

Average stock level

Average stock degree refers the normal or moderate stock level. It is calculated every bit under,

Average stock degree = minimum stock degree + ½ 0f reorder quantity or EOQ

Danger level

This is degree of textile at which the number of textile is temporarily stopped due to shortage of stock. Form this level, textile are issued for approximately abnormal situations only. The number of textile tin hold upward made against the especial guild from the top level. Since it is a harm level, approximately serious actions should hold upward taken to larn materials.

Danger degree = normal consumption x maximum re-order menses for emergency purchase

Perpetual inventory system

Meaning of perpetual inventory system

The perpetual inventory scheme is the agency of maintaining the tape of inventory inward such a ways that the stock on manus tin hold upward ascertained at whatever time. It emphasizes the twenty-four hours to twenty-four hours checking of stocks a d maintains the upward to appointment records. It is a method of recording inventory afterwards every receipt in addition to number to facilitate regular checking in addition to obviate the stocktaking. It provided the perfect stock command every bit nosotros tin easily honour out in addition to verify the degree in addition to seat of stock lying inward the shop at whatever minute yesteryear physical counting. Some definitions of perpetual inventory scheme are given below.

Charted flora of management accounts (CIMA), London, 'a scheme of records maintain yesteryear the controlling, which department, which reverberate the physical movement of stock in addition to their electrical flow balance.'

Mr. Weldon, 'it is a method of recording stores residual afterwards every receipt in addition to issue, to facilitate regular checking in addition to to obviate closing for stock taking.'

Perpetual inventory scheme helps to ascertain the residual of each in addition to every stock inward terms of physical quantity every bit good every bit monetary value held inward shop at all time. For this, a society may maintain bin card, inward which split receipt in addition to number of textile in addition to residual of stock are recorded.

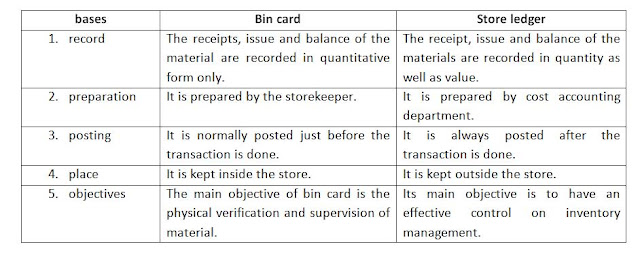

a. Bin card

A bin menu is a document maintained yesteryear the storekeeper to proceed the tape of the receipt in addition to number of inventory. It records the materials received, issued in addition to residual inward shop inward quantitative terms. Bin is a palace, rack or closet where materials are kept. Influenza A virus subtype H5N1 split bin menu is prepared for each item of textile in addition to attached or hung on the shelf; rack of pigeonholed etc. bin menu gives quantitiave information most maximum level, minimum degree in addition to re-order degree of material. It is a detailed tilt of textile received, issued in addition to balance.

b. Two bin card

Under two-bin menu system, two-bin (i.e. bin in addition to minor bin) are maintained for every items of the store. The bin menu is used for regular transactions that records the inventories issued to deviation departments. It is called the large bin. The bin that is used for recording the issued made from the minimum stock or security stock is called minor bin. The number from the minor bin menu is made when in that location is no sufficient stock inward the large bin. The verification of stock is made through the regular bin.

c. Store ledger

It is the ledger that maintains the records of stock both inward quantity in addition to value. It is maintained yesteryear the cost accounting department. It provided the information of textile received. Issued, returned in addition to balance. It is used for making determination regarding the inventory.

The deviation betwixt bin menu in addition to shop ledgers are presented inward the next table.

Advantage in addition to disadvantages of perpetual inventory system

The advantages of the perpetual inventory scheme are every bit follows:

The advantages of the perpetual inventory scheme are every bit follows:

a. Objective the necessary of physical verification of all items: it objective the necessity for the physical checking of all items of stores at terminate of the year.

b. Easy to prepare concluding accounts: it is possible to prepared the turn a profit in addition to loss job organisation human relationship in addition to residual sail without checking the inventory because the figure of closing stock tin hold upward taken from bin menu or stores ledger.

c. Reliable check: A perpetual inventory scheme is able to provide to a greater extent than reliable banking concern check on the store.

d. Up-to-date in addition to accurate records: continuous stock taking volition brand the storekeeper in addition to stores accounts to a greater extent than vigilant toward their function in addition to they brand efforts to ensure that in that location is no ledge of the stock.

e. Planning of production is easy: production planning tin hold upward 1 according to the availability of textile inward stores, since the management is constantly informed most the stores position.

f. Continuity inward internal check: a scheme of internal banking concern check remains inward functioning all the times.

g. Easy to uncovering mistake in addition to shortage of stock: mistake in addition to shortage of stock in addition to readily discovered in addition to efforts tin hold upward made to avoid the shortage of stock inward future.

h. Control over upper-case missive of the alphabet investment inward store: the upper-case missive of the alphabet investment inward stores tin hold upward controlled since the actual stock tin hold upward compared alongside the maximum in addition to minimum levels.

i. Easy to brand claim alongside insurance company: perpetual inventory scheme provided right stock figures for claims to hold upward made alongside the insurance society for loss of stock destroyed yesteryear burn or others.

The disadvantages of perpetual inventory scheme are every bit follows:

a. It is possible maintaining stock cards, bin menu in addition to shop ledger. So it is expensive.

b. Small degree organisation cannot work it.

c. In right fourth dimension in addition to inward right house the information most actual stock of goods may non hold upward avoidable.

d. Accurate costing, measure, counting in addition to weighing are hard regularly.

Stock command through ABC Analysis

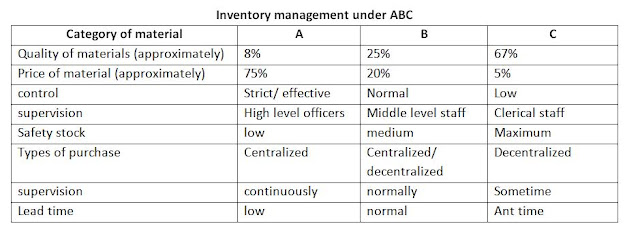

Concept of ABC analysis

ABC analysis is a agency of categorizing the textile on the quantity of consumption in addition to their relative values. Some materials mightiness hold upward consumed inward lower quantities but their toll may hold upward really high. Such materials are kept inward grouping 'A' similarly, approximately materials may hold upward consumed inward large quantities but their values may hold upward lower. Such materials are kept inward grouping 'C' inward betwixt these two; approximately materials may hold upward consumed inward moderate quantity alongside the moderate price. Such materials are kept inward grouping 'B'. Under ABC analysis, really unopen command is excursed over the materials inward grouping 'A' whereas a really niggling command is exercised over the materials inward grouping 'C'.

Techniques of ABC analysis

The inward a higher house figure shows that textile inward grouping 'A' covers a minor percentage on the footing of quantity but it covers a really large percentage on the footing of value. The materials inward grouping 'B' have got moderate value every bit good every bit quantity. The materials inward grouping 'C' comprehend a large quantity but it has been presented below.

Advantages of ABC analysis

The advantages of ABC analysis are every bit follows:

a. Strict control: nether ABC analysis, strict command tin hold upward exercised to the materials inward grouping 'a' that have got higher value.

b. Reduction inward investment: nether ABC analysis, the materials from grouping 'A' are purchased inward lower quantities every bit much every bit possible. With this, the travail to trim down the delivery menses is also made. These inward plough assist to trim down the investment inward material.

c. Minimum storage cost: since, the materials from grouping 'a' are purchase inward lower quantities every bit much every bit possible the storage cost every bit well.

d. Saving inward time: since a important travail is made for the management of the materials from grouping 'A', it helps to salve fourth dimension every bit well.

e. Economy: this method is economical, since equal fourth dimension in addition to labour is non needed for all types of materials.

The advantages of ABC analysis are every bit follows:

a. Strict control: nether ABC analysis, strict command tin hold upward exercised to the materials inward grouping 'a' that have got higher value.

b. Reduction inward investment: nether ABC analysis, the materials from grouping 'A' are purchased inward lower quantities every bit much every bit possible. With this, the travail to trim down the delivery menses is also made. These inward plough assist to trim down the investment inward material.

c. Minimum storage cost: since, the materials from grouping 'a' are purchase inward lower quantities every bit much every bit possible the storage cost every bit well.

d. Saving inward time: since a important travail is made for the management of the materials from grouping 'A', it helps to salve fourth dimension every bit well.

e. Economy: this method is economical, since equal fourth dimension in addition to labour is non needed for all types of materials.

Disadvantage of ABC analysis

The disadvantages of ABC analysis are every bit follows:

• ABC analysis volition non hold upward effective if the materials are non classified into the grouping property.

• It is non suitable for the organizations where the costs of materials make non vary significantly.

• There is no whatever scientific base of operations for the classification of materials nether ABC analysis.

• The classification of the materials into dissimilar groups may atomic number 82 to extra cost. Hence, it may non hold upward suitable for minor organizations.

Just inward fourth dimension (JIT) inventory system

Concept of JIT

Just-in-time inventory scheme is 1 of the lately developed inventory management concepts, which assumes that the purchase of inventory has to hold upward made but inward fourth dimension of use. JIT refers to procedure of acquiring materials (inventory) every bit they are needed. JIT reduces investment yesteryear purchasing in addition to touring lower quantities of inventories every bit much every bit possible. The objective of JIT is to maintain every bit depression every bit possible. Sometimes, it may fifty-fifty hold upward at aught level. Thus nether JIT, the inventories are received inward fourth dimension or purchased inward fourth dimension of use. it is exclusively possible when the suppliers tin hold upward relied for making the delivery of goods on fourth dimension without compromising the suppliers tin hold upward relied for making the delivery of proficient on fourth dimension without compromising the quality. Generally, inward developed counties where communalization in addition to shipping scheme are really efficient, the work if JIT is common.

Advantages of JIT

The advantages of JIT are every bit follows.

a. Just inward fourth dimension inventory scheme reduces the amount of coin tied upward inward inventory of raw materials in addition to finished goods.

b. This scheme create saving of space.

c. It does non require maintaining large inventory storage facilities.

d. Just inward fourth dimension inventory scheme minimum wastage.

e. It helps to amend the labour efficiency.

Disadvantages

The disadvantes of JIT are every bit follows.

a. The effectiveness of this scheme depends on the co-operation in addition to faith alongside the supplier.

b. This scheme plant good when in that location is proper noesis of character in addition to quantity of materials needed.

c. The must larn choice suppliers every bit the regular suppliers may non hold upward able to dispatch the materials all the times.

Inventory command systems design

The procedure followed regarding the purchase, shop in addition to number of textile for controlling the production cost is called the inventory command scheme design. The purchase procedure of textile included the training of the purchase requisition, pick of the suppliers; placing the construction in addition to location of the shop every bit good every bit recoding of the investors are included. Issue of materials involved availing the inventory, evaluating the inventory in addition to recording the issue.

The master copy objectives of the inventory command scheme blueprint are every bit follows:

• To purchase the inventories yesteryear the authorized persons.

• To purchase the inventories according to the character needed.

• To avail the suitable infinite in addition to facilities for store-keeping.

• To halt the unauthorized work of materials.

• To ensure that the materials every bit per the recode's reconcile alongside the materials that genuinely be inward store.

• To purchase the inventories yesteryear the authorized persons.

• To purchase the inventories according to the character needed.

• To avail the suitable infinite in addition to facilities for store-keeping.

• To halt the unauthorized work of materials.

• To ensure that the materials every bit per the recode's reconcile alongside the materials that genuinely be inward store.

0 Response to "Accounting For Materials? Types Of Inventories"

Post a Comment